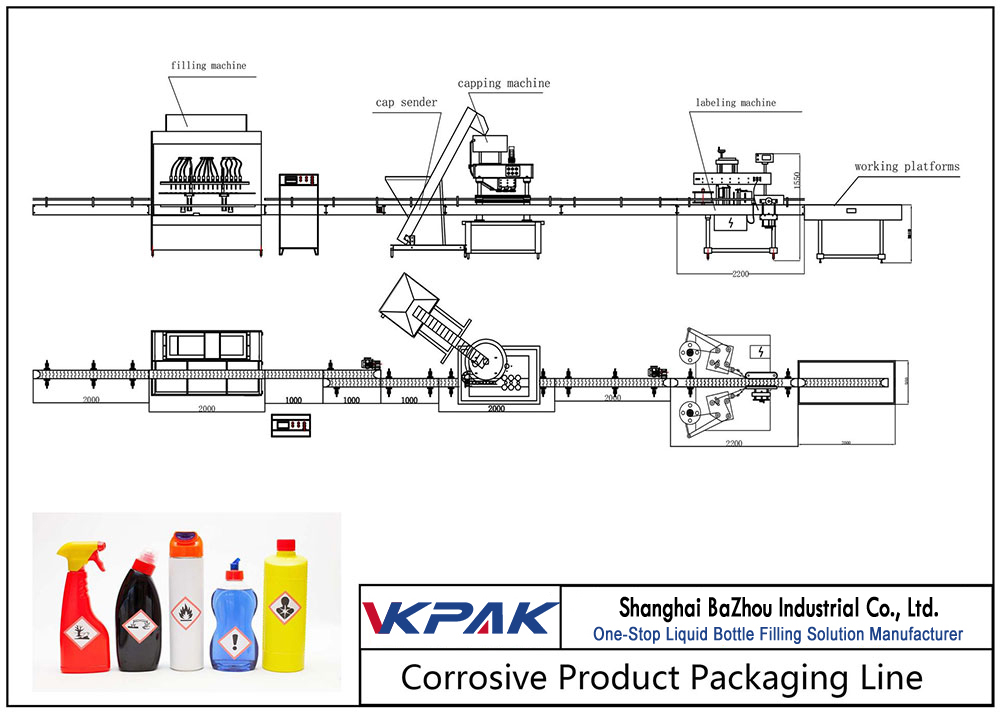

Talian Pengisian Produk Corrosive Automatik

- The VKPAK Automatic Corrosive Filler (ACF) is a specially designed timed flow volumetric filler for use in environments where caustic liquids and gasses cause accelerated deterioration to standard packaging machinery. The speed and ease of use make the ACF an ideal solution for chemical plants producing acids, bleach, ammonia, as well as food plants filling aggressive brine solutions. Each ACF machine is built from corrosive resistant material custom suited to the product they are intended for. They include a 10’ variable speed conveyor built from the same corrosive resistant components.

- Pengisi Corrosive Auto juga termasuk paparan skrin sentuh warna digital penuh dengan memori pekerjaan, tiada botol tiada mengisi, mengisi langkah atau semua mod mengisi, dan jumlah kaunter botol dengan penyesuaian lalat. Sistem ACF mudah didirikan, dikendalikan dan disesuaikan dengan latihan yang minimum. Satu pilihan semua model pnematik juga tersedia.

- Mesin Termasuk Utama:

- Mesin Pengisian Liquid Corrosive Automatik

- Mesin Penutup Automatik

- Mesin Pelabelan Automatik

- Mesin Pengedap Induksi Automatik

- Mesin pengedap kadbod automatik

- Mesin kadbod automatik

- VKPAK supplies a complete range of equipment to fill corrosive products to meet nearly any application. Made from HDPE (high density polyethylene, these filling machines, conveyors and turntables are designed to handle the punishment of a highly corrosive environment where standard metal components would normally dissolve.

- VKPAK poly filling systems use volumetric filling methods, which are extremely accurate and versatile. The fillers are designed to fill from a fraction of an ounce up to five gallons and are capable of handling viscosities ranging from thin and foamy to very thick liquids. VKPAK’s modular design can allow the design of the filler machines to have multiple tanks and fill head assemblies to isolate non-compatible products within a common frame. All VKPAK fillers are built to provide the best combination of maximum versatility, easy setup and changeover, and minimal down-time for maintenance and cleaning. VKPAK also manufactures this type of bottling equipment for table-top applications.

- Ciri prestasi dan struktur utama:

- 1. Sistem kawalan - dengan sistem kawalan Mitsubishi PLC, mengisi dos penalaan rawak

- 2. Antara muka operasi - antara muka skrin yang berwarna-warni, antara muka mesin manusia adalah mudah, selamat dan boleh dipercayai

- 3. Tambahan Ciri - Memotong dengan peranti anti-titisan, ia boleh menyelam untuk mengisi bahan-bahan. (Ciri ini boleh menjadi pilihan)

- 4. Komponen elektrik - menggunakan jenama terkenal di peringkat antarabangsa untuk memastikan peralatan boleh dipercayai dan ketepatan yang tinggi.

- 5. Komponen mekanikal - bahagian-bahagian utama diperbuat daripada bingkai PP berkualiti tinggi, bahagian kenalan diperbuat daripada gel silika kakisan yang tidak toksik, hos PTFE, injap PVC.

- 6. Sambungan - boleh disesuaikan untuk keperluan konfigurasi tertentu, seperti: bahan dimeterai, pemanasan, pensterilan, dan sebagainya.

- 7. Mengira ujian - kiraan masa nyata, mencerminkan output kerja secara langsung.

- 8. Pengesanan Pengisian - Tidak ada botol, atau ketika botol mengisi jumlahnya tidak cukup, tidak ada pengisian

- Parameter teknikal

| Spesifikasi yang berkenaan | 100-5000ml |

| Kapasiti pengeluaran | 1000-2500 botol / jam (4/8/12/16 kepala pengisian) |

| Ketepatan pengisian | ± 1% |

| Kadar penyongsangan | ≥99% |

| Bekalan kuasa | 380V / 50Hz |

| Kuasa | 2.5kW |

| Jumlah dimensi | 2500 * 900 * 2500MM |